|

|

Sales & Support

Request A Quote -

Select Language

|

|

|

Auto Calibration System

|

Product Details:

Payment & Shipping Terms:

|

| Product Name: | Calibration System | Feature: | Auto Calibration And Test System |

|---|---|---|---|

| Usage: | Improve Production Efficiency | Signal Source: | Output Voltage/ Current Signal |

| Input/output: | 0~5V/4~20mA | Computer Requirement: | Memory 512M, Hard Disk 80G, Windows XP System |

| Highlight: | energy monitoring system,energy meter system |

||

Auto Calibration System

Profile

AT2100 is suitable for motor protector manufacturer to test, auto-calibrate and inspect the product, so as to improve production efficiency and reduce production cost.

Main function

Calibrate the measuring functions of motor protector, including Voltage, Current, Active power, Reactive power, Power factor, Frequency and analog input and output;

Calibrate the protecting functions of motor protector, including Lack Voltage protection, Over Current protection, grounding / leakage Current, PT disconnection and motor protection execution time;

Fast and efficient calibration and inspection in production thru special tools;

Each calibration data can be exported as excel table, easy to record and save;

Customize various protection functions of low Voltage motor protector according users’ requests.

Testing System

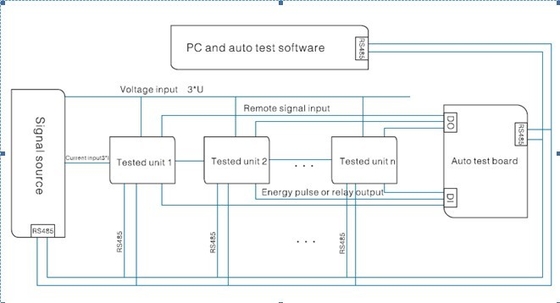

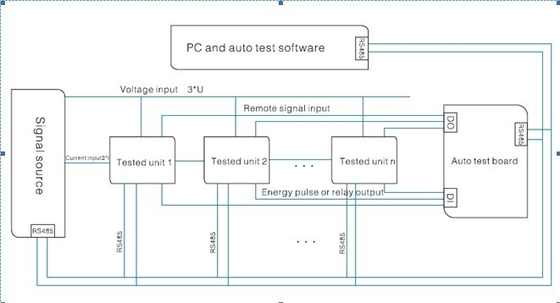

![]()

Signal Source

AT1015 Low Voltage Motor Protector Calibrator can be used to output Voltage/ Current signal, the signal output content can be customized.

Input/ output board

Special I/O signal, analog 0~5V/4~20mA input/output signal inspection.

Tooling rack

Clamp and fix tested units fast, improve production and inspection efficiency; test 8 units one time (the quantity depends on user’s requirement and power of tested loop).

Auto calibration and test software

Computer requirement: CPU P31G, memory 512M, hard disk 80G, Windows XP system.

Calibration mode: The software sends calibration parameters to tested units thru internal test standard.

Inspection mode: The software has various protection modules (overtime start, short circuit, locked rotor, overload, thermal by overload and so on, also can add modules according the requirement), configure inspection parameters of each module according the user’s needs, the inspection can be done manually or automatically.

The software accomplishes the quality check of test units according to the execution parameters which measured by I/O board and internal test standard (can be modified and set), and then export test results and test units serial number in the set report format, which is convenient for data inspection and check.

Contact Person: Miss. Maple

Tel: +86 0755 83426356